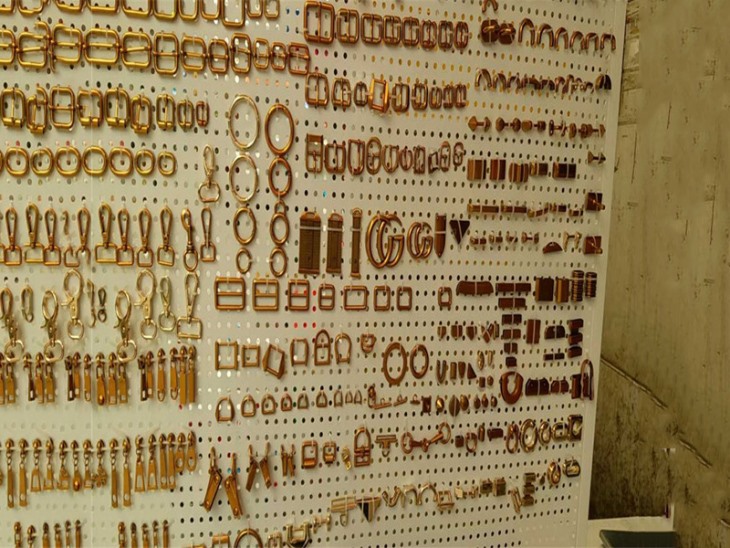

Metal plating varnish

Metal plating varnish

First, the characteristics:

1. Excellent adhesion, high hardness and good resistance.

2. Good transparency, high gloss and fast drying.

3. Good salt spray resistance and chemical resistance.

Matching ratio:

Varnish: curing agent: thinner = 100:10:100--200

Drying conditions:

Bake for 30 minutes from dry (24 hours at room temperature) or 60 ° C to 80 ° C.

Since the high temperature baking is not required, the silver plating layer is not easily discolored.

The reason for the discoloration of the coating is mainly that the coating is not resistant to corrosion in an aggressive medium (including air), and oxidation or other chemical reaction occurs on the surface. The anti-tarnish treatment of the coating can be noted in the following aspects.

First, the electroplating process is optimized, and the process specifications are strictly enforced, which can greatly reduce the tendency of the coating to change color. For example, avoiding poor cleaning after plating, high current density, and high bath temperature are all beneficial to avoid yellowing of the tin plating layer.

The second is to carry out plating on the plating. For example, copper alloys, especially imitation gold plating, are prone to discoloration. If a layer of 0.02-0.2 μm gold is plated on the coating, gold is a precious metal and is not easily discolored in the air, which can make electroplating products for a long time. Does not change color. This kind of technology is used throughout Japan and Hong Kong.