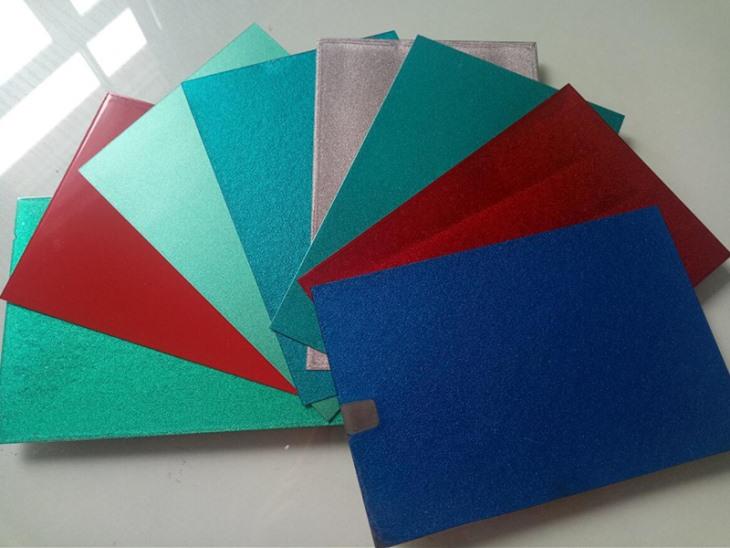

Metallic paint, English name Metallic Paint, metal paint refers to a room temperature curing coating with fine metal particles in the paint base, is a popular automotive topcoat. A fine aluminum particle is added to the lacquer base, and the light is reflected on the aluminum granule and then reflected by the aluminum granule through the lacquer film.

Epoxy anti-rust paint is divided into metal epoxy anti-rust paint, concrete epoxy anti-rust paint, wood epoxy anti-rust paint, etc. according to the application substrate.

1. Metal epoxy antirust paint:

Carbon steel, cast iron (epoxy zinc-rich, HD200 epoxy primer, HD500 epoxy primer),

Galvanized steel, stainless steel, aluminum alloy (HD1000 epoxy primer),

Hot spray zinc, aluminum spray (HD1500 epoxy paint)

2, concrete epoxy anti-rust paint: At present, there are two main categories of epoxy resin sealer and silane impregnating agent.

3, wood epoxy anti-rust paint: there are lacquer, wood wax oil and other varieties.

Paints classified according to the substrate are usually used directly to handle good surfaces. There are no other coatings in between. Most require a composite coating of the same type or other coating.

Epoxy anti-corrosive paints are classified as follows:

Epoxy paint, acrylic polyurethane paint, fluorocarbon paint, silicone top coat, epoxy composition (such as epoxy coal tar paint, epoxy phenolic paint), ethyl silicate (for example: inorganic zinc-rich paint) , high chlorinated polyethylene paint, chlorinated rubber paint, silicone paint, etc.

Epoxy anticorrosive paint according to the classification of use

According to the "GB2705-2003-T coating product classification, naming and model" anti-corrosion coatings belong to a sub-category of industrial coatings, including bridge coatings, container coatings, buried pipeline epoxy anti-rust paint, high temperature coatings and other anti-corrosion coating.

Related Industry Knowledge

- Floor paint construction acceptance standard floor paint construction plan

- Characteristics and construction technology of glass wine bottle paint

- Process difference and advantages and disadvantages of vacuum electroplating varnish and water electroplating varnish

- Waterborne metal baking paint spraying precautions

- About the construction of water-based glass bottle paint

- What are the problems with the epoxy floor paint in the underground parking lot?

- Double propylene polyurethane sealant construction process and precautions

- The difference between art floor and epoxy floor Guangzhou Tianmai supply high quality floor paint

- Several points that must be known before the construction of self-leveling epoxy floor paint

- Waterborne metal paint has become a mainstream product in the waterborne coating industry.

- Epoxy self-leveling maintenance knowledge

- Comparison of waterborne glass lacquer (glaze) and oily glass lacquer

- What should I pay attention to in waterborne metallic paint?

- How does electroplating varnish ensure a longer-lasting color?

- Introduction and application of colored wear-resistant pavement coating

- What are the advantages of colored wear-resistant pavement coatings?

- Which is better for water-based glass paint and oil-based glass paint?

- Take your considerations for analyzing waterborne metallic paints