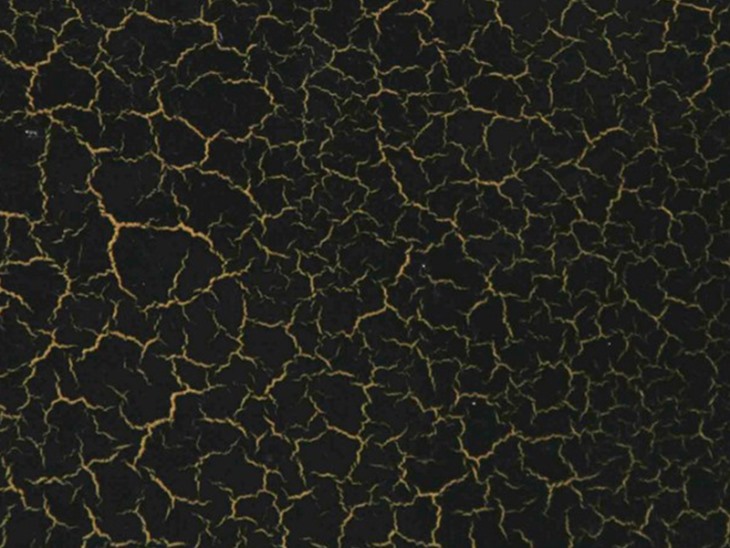

The crack is too thin and the crack surface is not cracked.

Because the crack picture appears by the rupture of the paint film, it can't be sprayed too thick at one time. Otherwise, the crack will be very thin and the crack surface will not crack. The oil quantity and the number of guns should be controlled to select the better picture. Because the crack paint is sensitive to temperature and humidity, the temperature is too low, the crack is fine or even cracked; the temperature is too high and the marking is large. Therefore, the ambient humidity is too large, the temperature is too high, too low is not suitable for construction, generally at a temperature of 25 ° C, relative humidity of 75% is better, to avoid adverse effects. There are also some conditions because the fundamental characteristics of the cracked paint cannot be grasped. When the primer is applied, the non-nitro-based paint (including aluminum powder, pearl powder, gold powder and other colored primers) can form the crack paint . The lacquer is useful for blending and exhibiting another crack characteristic. However, the solution is very simple. For the non-nitro-based paint primer (including aluminum powder, pearl powder, gold powder and other colored primer), spray nitro varnish 1-2 before spraying the crack paint. Wait for about 10-20 minutes (depending on the ambient temperature condition). When the nitro varnish is in the semi-dry state, the crack paint will be sprayed immediately.

Uneven crack size

The crack size is evenly affected by many factors, especially the construction personnel's skill in grasping the spraying skills. This can only strengthen the training and training of the construction personnel. There are no other shortcuts. But we must also grasp the principle of crack size: if the demand for large cracks, the thickness of the primer film should be thicker, and the crack paint should also be sprayed 2-3 times, and the gas volume does not need to be too large; if small cracks are required, Then the primer does not need to be too thick, and the crack paint should be sprayed thinner, and the gas volume can be slightly larger. However, the uniformity of spraying should always be adhered to, and even a uniform crack can be obtained. In particular, only one spray can be applied during spraying. It should be successful in one shot. It should not be returned to the gun or the gun. If the thickness is uneven, the gun will be re-punched, and the gun will form a crack. The disadvantage of uneven size. (Before the spraying process does not terminate, the crack can be sprayed on the crack to control the crack size, but the construction workers have very high technical methods, and the general construction personnel do not advocate the use).

Paint cracked after crack cracking

Because the cracked paint has large powderiness, large shortening, low flexibility and poor adhesion, the paint surface is boring and shortened, and is relatively simple to fall. In order to make the crack paint strong and durable, it is more beautiful and bright. After the crack paint is dry, it is polished and smoothed. The surface is cleaned and cleaned. The semi-matt, matt nitro varnish or polyester paint, polyurethane paint, two-component PU varnish, etc. . When the varnish is applied, the clear lacquer should be coated with a thin spray (at least twice). Some construction workers in the construction lack understanding of the fundamental characteristics of the cracked paint, and then use non-nitro-based paints (including aluminum powder, pearl powder, gold powder and other colored primers) after the base is scraped and put on. The base is soft, and the internal stress of the cracked paint is high, and the tensile strength is high. In the shortening process, the soft base is turned upside down to form a large area of peeling and falling off. However, the solution is also very simple, no need to rework from scratch, the use of general scratching putty and other bases and then the construction of non-nitro-based paint (including aluminum powder, pearl powder, gold powder and other colored primer) Use polyester primer or polyurethane primer, such as strong primer, strong film, and hard layer, firstly close the original layer, then spray the aluminum powder, pearl powder, gold powder and other paints from the head. -2 roads, after dust removal and cleaning, it is possible to spray crack lacquer 1 way, cracking can occur, and the surface layer lacquering method is the same as above.

Related News

- What is the difference between waterborne glass paint and oily glass paint?

- Bubble problem in waterborne metal paint film formation

- Waterborne metal paint construction process

- Do you know the reason why glass lacquer can extend the life of log furniture?

- On the colored road, the old driver takes you on the road! Guangzhou Tianmai supply color wear-resistant pavement coating

- Characteristics and construction process of water-based crack paint

- In the hot summer days, the colored pavement will provide you with “heat and heat”. Guangzhou Tianmai supplies colored wear-resistant pavement paint.

- Waterborne glass paint type and application precautions

- How to apply water-based crack paint? Tianmai Chemical will solve your problems!

- Can epoxy anticorrosive paint be used outdoors?

- How do you know how to build self-leveling epoxy floor paint?

- What is the reason for the poor hardness of the floor paint?

- Water-based crack paint use attention method you should know

- Selection and construction process of epoxy antirust paint

- Problems that should be paid attention to during the construction of industrial floor paint

- Epoxy anti-rust paint adhesion ability is good

- Common problems in the construction of epoxy floor paint

- Comparison between waterborne glass paint and oily glass paint

- Waterborne electroplating varnish formula

- What are the advantages of waterborne metallic paint?