Waterborne metal lacquer is the current domestic steel structure anti-corrosion material, which can transform the rust layer on the metal surface into a favorable protective layer, which is unmatched by solvent-based paint. The relevant knowledge of water-based metal lacquer is as follows:

First, the birth of water-based metal paint

For a long time, metal coating relied entirely on solvent-based paints and paints. During the Second World War, Germany was the first to develop water-based metallic paints because of the lack of grease. This product has shown unparalleled superiority. After the completion of the Second World War, some developed regions in Europe and the United States, because they attach great importance to avoiding environmental pollution and saving energy, pioneered the development of water-based metallic lacquers and rapidly developed them into powdered, water-based and solvent-free. Because water-based metal lacquer has the advantages of no pollution, energy saving, better quality and convenient operation, since the beginning of the last century, the rapid development of the steel industry in Germany, the United States, Britain, France, Japan and other countries began to produce and use Waterborne metallic paints. At present, the production value of waterborne metallic paints in Europe and the United States has accounted for 78% of metallic coatings, and is carried out at a faster rate.

Since the 1990s, China has followed the large-scale export of industrial products and started to use imported water-based metallic paints. In order to reduce costs, in recent years, the development and production of waterborne metallic paints have been established in China, and they have been applied and promoted very quickly.

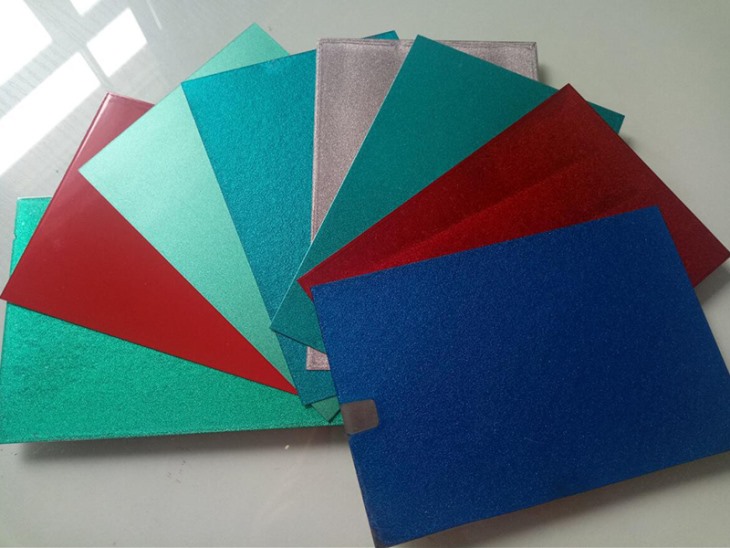

The paint is based on organic solvents. In the process of application, it also needs to participate in a large number of products such as banana water and Tianna water, which contain harmful diluents. The formaldehyde, benzene and xylene contained in the paint are all carcinogenic substances. Pollution and human health pose great dangers, so it is called "invisible killer." Water-based metal lacquer is made of water as the medium, using multi-component synthetic resin as the base material, participating in various anti-corrosion additives, and being prepared according to the chemical reaction principle of chemical conversion, complex and reaction, and multi-pass production process. The water-based metallic paint reacts with the active rust under the effect of inorganic acid, transforms the rust into a new stable protective layer, and firmly adheres to the metal surface to form a dense shutdown layer and a protective layer, thereby achieving the anti-corrosion intention. Because people have always relied on solvent-based paints, they can't get rid of the misunderstanding of solvent-based paints. They think that water-based metal paints are not as good as paint. It turns out that the film is evaporated and dried at the end of the film formation is a parallel film, while the water-based metal paint is a polymer film. It is a thick-grain film, the latter is the real high-end film, its protection and anti-corrosion performance is much higher than paint.

Third, the superiority of waterborne metal paint

1. No irritating odor, no harmful substances such as benzene, no pollution to the environment, no damage to the human body, it is a true green environmental protection product, which is conducive to civilized construction and meets the social requirements for environmental protection.

2. It is suitable for construction in all kinds of steel structure objects. It only needs to remove surface oil and sand, remove the floating rust, and then use rust, spray, dip and roll to construct, simplifying the construction process and reducing the labor intensity. Reduced production costs.

3, water-based metal paint flame retardant, anti-explosion, transportation, storage, no flammable danger during use, thus ensuring safe production.

4, water-based metal paint at room temperature boring at a fast time, strong conjunctiva, strong adhesion, paint film acid, alkali, weather resistance, anti-corrosion effect and anti-corrosion life is more than twice the same level of solvent-based anti-rust paint, greatly Reduce the construction cost and material cost of maintenance coating.

5, the use of water-based metal paint is prohibited to participate in banana water, Tianna water or gasoline and other organic, inorganic solvents and thinners, the paint must be evenly mixed before use, such as excessive viscosity, can participate in the appropriate amount of tap water dilution, after the completion of construction Construction materials, equipment, containers, etc. need only be cleaned with tap water. It is forbidden to use other solvents, which not only ensures that the construction environment is free from pollution, construction workers are harmless, but also reduces production costs and saves energy.

6, water-based metal paint does not evaporate, high solid content, not only to ensure the quality of the product in the storage process, and the painting area is at least one-third higher than the paint.

The birth of water-based metallic paints is not only a high-quality, low-cost, safe and environmentally friendly green product coated with various metal materials, but will eventually replace solvent-based paints. Early use of early benefits, early production quality and corporate image.

Related Industry Knowledge

- Floor paint construction acceptance standard floor paint construction plan

- Characteristics and construction technology of glass wine bottle paint

- Process difference and advantages and disadvantages of vacuum electroplating varnish and water electroplating varnish

- Waterborne metal baking paint spraying precautions

- About the construction of water-based glass bottle paint

- What are the problems with the epoxy floor paint in the underground parking lot?

- Double propylene polyurethane sealant construction process and precautions

- The difference between art floor and epoxy floor Guangzhou Tianmai supply high quality floor paint

- Several points that must be known before the construction of self-leveling epoxy floor paint

- Waterborne metal paint has become a mainstream product in the waterborne coating industry.

- How to choose epoxy floor paint?

- Floor painting paint anti-static floor paint construction difference

- Salt spray resistance galvanizing method

- The difference between metallic paint and pearl paint

- The difference between water-based electroplating varnish and general varnish

- Details of the characteristics of glass paint

- Glass paint - feels smooth, you want to have it at first glance

- Electroplating varnish if it lasts for a long time

- Analysis and introduction of waterborne glass paint

- What are the advantages of colored wear-resistant pavement coatings?